The fumigation process will include random container checks in which a random container is scanned using high tech infra-red scanners.

The scanners can scan the surface of clothing, paper, cardboard, wood, masonry, plastic and ceramics including additional material in order to detect traces of disease, rodents, faeces and insects.

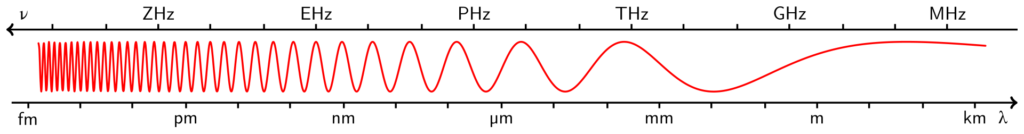

Our scanners represent the latest generation of such scanning capability as the infra-red scanner’s wavelength is completely harmless to human beings compared to the previous generation of x-ray scanners.

Once a scanner identifies rodents or insects within the container our experienced fumigators will seal the cargo to created a sealed chamber. The airtight container will prevent gas or air getting into or out of the container.

The first phase will be to use insecticide liquid spray to eradicate rodents, pests and insects.

Bio-Production Insecticide Liquid is an effective, user friendly, ready-to-use, water based, approved insecticide for use on carpets, upholstery, fabrics and hard surfaces.

Simply spray on and leave to dry naturally, the insecticide is ideal treatment for eradication of infestations and control of all crawling and flying insects including fleas.

This insecticide is ready to use and suitable for the treatment of infestations in & on all porous and non-porous surfaces.

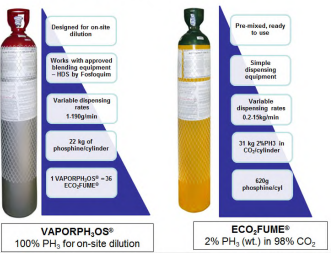

A fumigation gas such as Phosphine (pH3) is inserted into the container the gas which targets all pests within the product and around any packaging.

The end-use product, ECO2FUME™ is a cylinderized, compressed gas containing a mixture of 2% phosphine by weight (2.6% by volume) in carbon dioxide (98% by weight).

The benefit of using Phosphine in container fumigation is that it does not leave any traces of residues on the cargo product. This means that the product remains in perfect condition after the fumigation is complete. The fumigation process is carefully planned from start to finish.

The gas concentration levels are electronically monitored throughout the process to ensure levels remain stable.

After 1-2 days we’ll return to remove the sheet and to check the levels again. At the end of the treatment, a fumigation clearance certificate will be issued.

This certificate is issued as a result of the gas levels being below the workplace exposure limit (WEL). This confirms that the area is now safe for workers to enter and handle the product.

PREVENTING GLOBAL BIOSECURITY RISKS AND HUGE FOOD LOSSES

POST HARVEST FUMIGATION IS LIMITED TO CONFINED SPACES, INVOLVES SMALL CHEMICALS VOLUME USAGE: silos, warehouses, containers, bulk shiploads in intercontinental trade. NO RELEASE IN OPEN SPACES

PREVENTING FOOD LOSSES REDUCES GLOBAL PRESSURE ON FOOD PRODUCTION According to various surveys, stored food losses due to pests range from 5% to up to 1/3 of total stored consignments

Phosphine (pH3) is used to control pests, such as insects and rodents, in indoor environments. Stored grains, animal feed, and tobacco can be fumigated with phosphine gas to protect from pests.

Phosphine cannot contaminate food or water. PH3 breaks down when it comes into contact with water. As a gas, it is very unlikely that it will contaminate any agricultural crops.

Phosphine Detectors will be used for personal protection, measuring the PH3 levels as well as continuous container monitoring.

Methyl Bromide is an efficient fumigant but as an Ozone Depletion Potential material it was to be phased out following the Montreal Protocol. Phosphine is a safe and green alternative.

Phosphine carries less health risks than Methyl Bromide as Methyl Bromide is a toxic material which poses other risks and harmful effects, in particular occupational neurologic effects upon prolonged exposure for fumigation employees

PREVENTING GLOBAL BIOSECURITY RISKS AND HUGE FOOD LOSSES

POST HARVEST FUMIGATION IS LIMITED TO CONFINED SPACES, INVOLVES SMALL CHEMICALS VOLUME USAGE: silos, warehouses, containers, bulk shiploads in intercontinental trade. NO RELEASE IN OPEN SPACES

PREVENTING FOOD LOSSES REDUCES GLOBAL PRESSURE ON FOOD PRODUCTION According to various surveys, stored food losses due to pests range from 5% to up to 1/3 of total stored consignments

Correct health and safety needs to be ensured at all times for PH3 fumigation as the gas is not only toxic to pests but also to humans if correct health and safety measure are not taken.

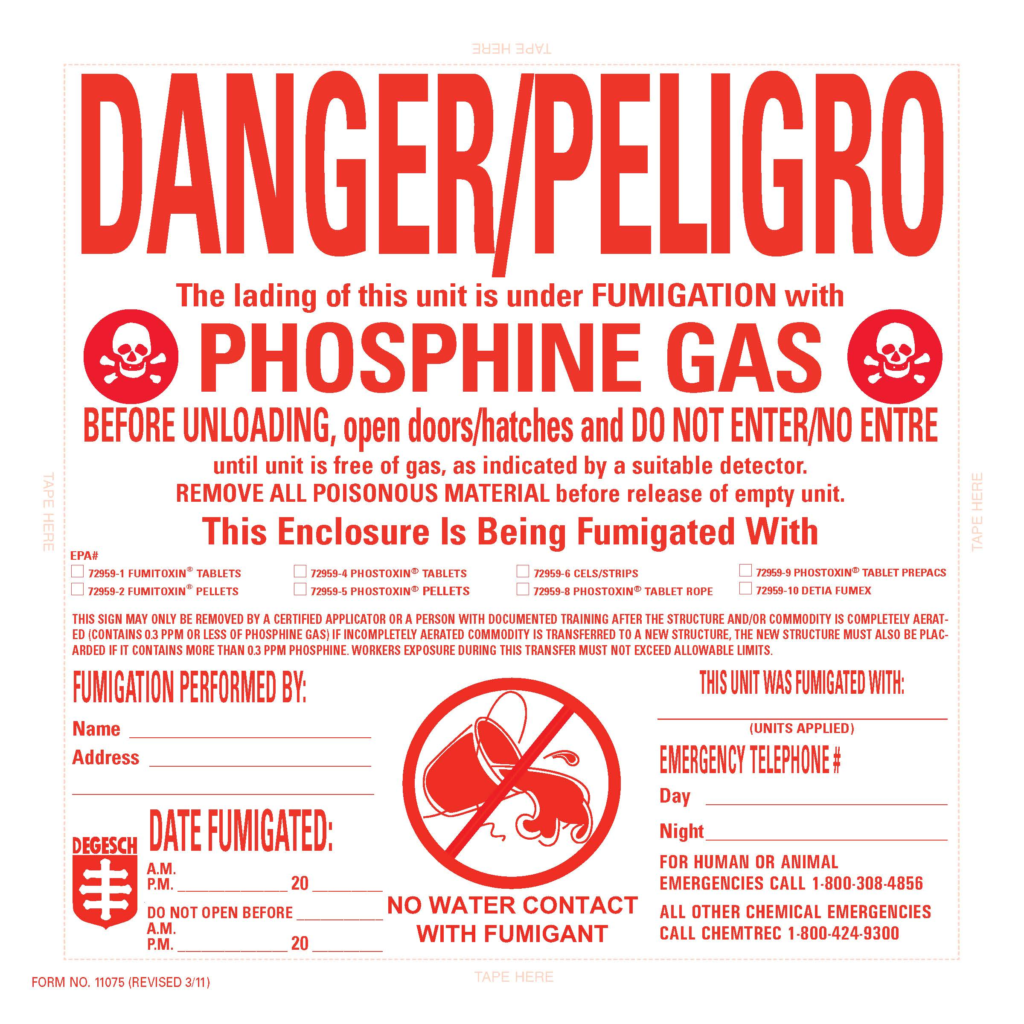

To avoid risk to worker health all fumigated containers must be labelled with warnings that show that they are fumigated.

Fumigants added to the containers must be distinguished and separated from unfumigated containers in order to minimise risk to port employees.

Correct PPE will be worn by all fumigators such as protective hazmat suit, gas masks, goggles and industrial gloves and shoes. Fumigants can enter the body though inhalation and by absorption through the skin after dermal exposure.

All workers will receive regular training and instruction on the procedures to be used and the maintenance and correct use of PPE.

HSCS provides expert disease prevention and biosecurity services at Somaliland’s ports, ensuring safe trade and environmental protection through international standards.

© HSCS Container Services | Powered by Brand Awareness Co