The empty export container cleaning process typically involves inspecting for damages, removing visible debris with a broom or blower, thoroughly washing the interior and exterior with high-pressure water and detergent, followed by sanitization and drying.

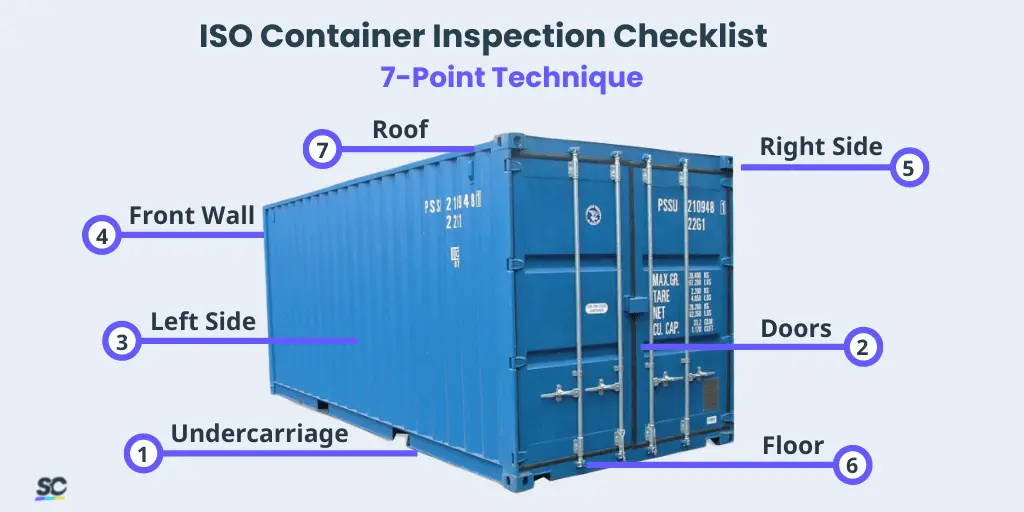

Inspect for Damage:

Once the container is unloaded and returned to the carrier’s depot, the depot’s operations team conducts a full check for damage or defects.

Remove Debris:

The container’s interior and exterior are cleaned to remove loose dirt, dust, and any visible debris using sweeping, brooming, or a leaf blower.

Air Out:

A leaf blower or air compressor can be used to clear out any detached debris or dust.

Wash Interior and Exterior:

A high-pressure water jet with specialized cleaning agents is used to wash both the interior and exterior of the container.

Start from the Back:

Begin cleaning from the back of the container and move towards the front to avoid reintroducing dirt or debris.

Use a Pressure Washer:

A pressure washer is recommended for cleaning the container, and safety glasses or goggles should be worn while operating it.

Pay Attention to Corners and Ceilings:

Ensure the corners, walls, and ceilings of the container are thoroughly cleaned.

Address Rust:

Small rust spots can be cleaned with a wire brush and treated with vinegar to prevent further corrosion.

Decontaminate (If Necessary):

If the container previously held hazardous or contaminated materials, follow proper decontamination protocols, possibly requiring a solvent-based cleaning.

Sanitize:

Depending on the container’s previous use, it may undergo sanitization to kill bacteria, viruses, or microorganisms.

Use Specific Sanitizing Agents:

Certain sanitizing agents may be required based on the nature of prior cargo.

Drying:

After cleaning and sanitization, the container is thoroughly dried to prevent moisture buildup and mold or bacteria growth.

Ventilate:

Ensure adequate ventilation to aid the drying process.

Inspect for Damage:

After cleaning, a final inspection is conducted to verify the container’s cleanliness and seaworthiness.

Repair:

Any damage or defects identified during the inspection are repaired before the container is released.

Once the container is certified as clean, seaworthy, and ready for use, an Equipment Interchange Receipt (EIR) or Container Release Order is prepared.

Additional Notes

Container Emptying:

Before the washing process begins, the internal content of the container must be completely removed using special equipment.

HSCS provides expert disease prevention and biosecurity services at Somaliland’s ports, ensuring safe trade and environmental protection through international standards.

© HSCS Container Services | Powered by Brand Awareness Co